Innovation for the construction industry

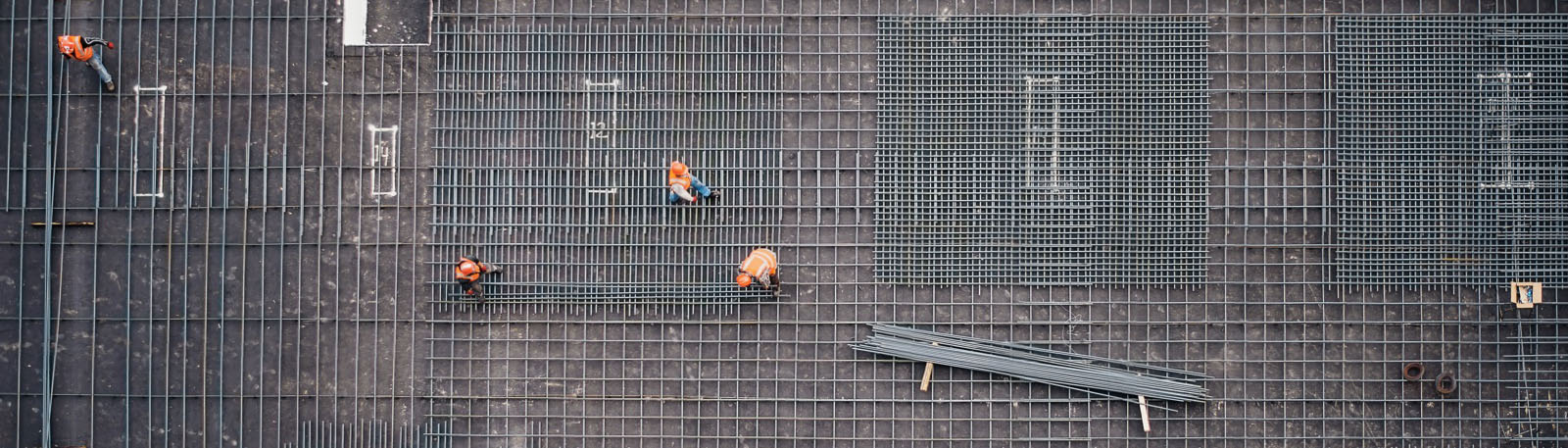

MEET THE CONSTRUCTION

MATERIAL OF THE FUTURE

About Us

Basalt Technologies UK Ltd is a manufacturing company based in Leighton Buzzard, UK producing a range of downstream products from Continuous Basalt Fibre (CBF) for construction industry. These products include Bastech® Basalt Fibre Reinforced Polymer Rebar.

BASTECH BFRP Rebar replaces steel. Decarbonising concrete reinforced structures

Technology

In production of BASTECH® rebar two components are used: Continuous Basalt Fibre (CBF) and inert resin. CBF is a product of a single step extraction from molten basaltic rock without the use of any chemicals. Basalt Rock is a single-component resource of natural origin; it is an ecologically clean raw material. CBF is then mixed with resin and pulltruded through a pulltrusion line to produce the final product.

Benefits

Our production lines are designed and built to our company specifications. BASTECH complies with UK Building Regulations (England and Wales 2010 as amended & Scotland 2004 as amended), International Residential and Building Codes, ASTM and Florida Department of Transportation (USA).

Sustainable

The main components of Bastech® rebar — basalt fibre is manufactured directly from basalt rock in a single-melt process, and comprises only of a single raw material. On average 60% less CO2 emission than steel.

Stronger

Bastech® rebar is 4 times lighter and 2.5 times stronger in tensile strength than its steel counterpart .

Rust free

Bastech® rebar is naturally resistant to sea water, alkali, microorganisms and acids. It doesn't rust.

Products

Bastech® BFRP rebar supplied in bar forms from 4 to 32 mm diameter up to 12 m length or in coil forms up to 12 mm in diameter in 100-150 m length and bent bars (shape codes), microbars replacing steel fibres, chopped fibres replacing polypropylene and glass fibres to enhance crack resistance in concrete structures.

Bastech® BFRP rebar is produced by the method of pultrusion and polymer. Due to unique performance properties, it is an efficient and cost effective alternative to steel reinforcement.

All Basalt products are manufactured in the UK (Wing, Buckinghamshire) to meet the basic regulations of BBA, ISO 10406-1: 2015 and ICC-ES AC454.

Lead time: EX Stock to 15 Days

Bespoke mesh manufacturing service is offered to incorporate specific client’s requirement.

Maximum mesh size: 4 m x 12 m by 20 mm diameter.

Please apply for quotation: info@basalt.tech.

Deliveries to all parts of United Kingdom.

BASTECH Basalt rebar makes structures last longer

BASTECH® FRP rebar

Main advantages:

74% less in embodied carbon than steel

- 2.5 times stronger than steel.

- 4 times lighter than steel.

- Resistant to sea water, alkali, and acids. It does not rust.

- Moisture penetration from concrete does not spall.

- Reduction in concrete cover.

- Needs no special coating like glass fibre rods.

- Bastech rebar has the same thermal coefficient expansion as concrete.

- Bastech rebar is easily cut to length with regular tools.

- Non-conductive, ideally suited to areas as MRI and data centres.

- On average 60% less CO2 emission in final concrete structures due to production process, logistics and material optimization.

- Overall project cost is less than with steel rebar.

- Savings on logistics and installation.

Technical specifications

| Property | Value |

|---|---|

| Diameter | 4-32 mm |

| Length, up to | 12m (Ø to 8 mm –in coils 50-100 m) |

| Tensile strength | 1,200-1,400 МPa |

| Elasticity modulus | 50,000-55,000 МPa |

| Density | 2 g/cm3 |

| Heat conductivity factor | < 0.46 W/(m°С) |

| Coefficient of extension | 2.5 % |

| Electric conductivity | dielectric |

| Corrosion and chemical resistance | very high |

| Magnetic characteristic | non-magnetized |

| Heat stability | up to 200°C |

Clients